What Is The Permanent Magnet Synchronous Motor?

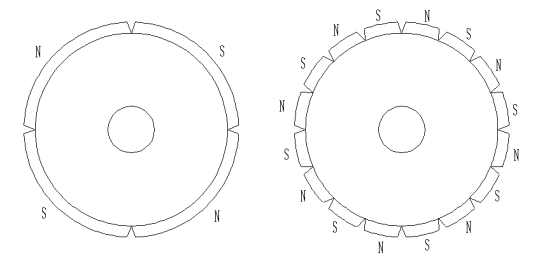

The PERMANENT MAGNET SYNCHRONOUS MOTOR is mainly composed of the

stator, rotor, chassis, front-rear cover, bearings, etc. The

structure of the stator is basically the same as that of ordinary

asynchronous motors, and the main difference between the permanent

magnet synchronous motor and other kinds of motors is its rotor.

The permanent magnet material with pre-magnetized (magnetic

charged) magnetic on the surface or inside the permanent magnet of

the motor, provides the necessary air gap magnetic field for the

motor. This rotor structure can effectively reduce the motor

volume, reduce loss and improve efficiency.

Analysis of the principle of the technical advantages of permanent

magnet motor

The principle of a permanent magnet synchronous motor is as

follows: In the motor's stator winding into the three-phase

current, after the pass-in current, it will form a rotating

magnetic field for the motor's stator winding. Because the rotor is

installed with the permanent magnet, the permanent magnet's

magnetic pole is fixed, according to the principle of magnetic

poles of the same phase attracting different repulsion, the

rotating magnetic field generated in the stator will drive the

rotor to rotate, The rotation speed of the rotor is equal to the

speed of the rotating pole produced in the stator.

Due to the use of permanent magnets to provide magnetic fields, the

rotor process is mature, reliable, and flexible in size, and the

design capacity can be as small as tens of watts, up to megawatts.

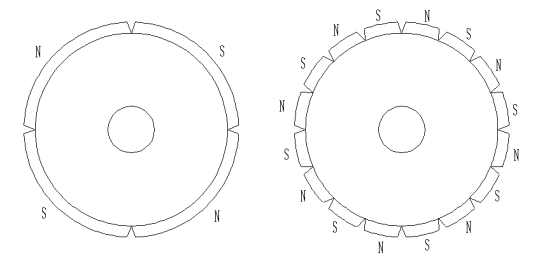

At the same time, by increasing or decreasing the number of pairs

of rotor permanent magnets, it is easier to change the number of

poles of the motor, which makes the speed range of permanent magnet

synchronous motors wider. With multi-pole permanent magnet rotors,

the rated speed can be as low as a single digit, which is difficult

to achieve by ordinary asynchronous motors.

Especially in the low-speed high-power application environment, the

permanent magnet synchronous motor can be directly driven by a

multi-pole design at low speed, compared with an ordinary motor

plus reducer, the advantages of a permanent magnet synchronous

motor can be highlighted.